During the last 8 years Geoteam CJSC has held 11 public hearings and more than 170 meetings with the communities. Taking into consideration the fact that the Amulsar mine is not being operated yet, the number of such community meetings is unprecedented. During these 8 years representatives of the affected communities have been provided with the details of the Project, issues have been discussed and responses given to any question raised. We have achieved an atomosphere of mutual trust and continuous open communication with the communities.

Nevertheless, even if one community resident is not satisfied with the answers to his/her questions, we are happy to discuss the questions addressed to us in the form of the open letter sent on March 12th.

Below is the brief content of the questions and the answers of the Company specialists:

1. Since 2011 the location of the heap leach facility has changed three times. “…What advantages does the selected area have as compared to the first two; whether the ecological, health and environmental risks are smaller or greater, since the area is closer to the communities than the previous ones”.

Read also

First of all, we would like to remind that about 600 heap leach facilities are operating all over the world, including in the USA, Canada, Australia, Chile, Russia, etc. Some of them are adjacent to communities, forests, and water resources. The Amulsar HLF will be a modern facility, subject to current best-practice design principles.

A geotechnical survey is carried out before selecting a location for the heap leach pad, and if the area meets stability, safety, and other technical criteria, it is deemed suitable. In this respect, two former locations selected in 2011 and 2013 were not significantly better or worse as compared with the current location.

According to the specialists and independent experts, the pad could operate safely for the environment in either the two former locations or the currently selected one.

However, two amendments were made in the Armenian legislation during the last 3 years. According to the first amendment, the immediate impact zone of Lake Sevan was extended in 2012 to cover the area where the heap leach facility was planned at the time, prohibiting ore processing in this area. And according to the second amendment, a 3 km buffer zone was set in 2013 around the inactive Spandaryan-Kechut tunnel, and this area was also considered as part of the Lake Sevan immediate impact zone.

Irrespective of our belief that both the first and second locations would have ensured safe operation of the pad from environmental, health or other viewpoints, to stay compliant with the Armenian legislation the Company has changed the pad location.

The new location was selected as a result of the two-month activity of the joint working group with the RA Government.

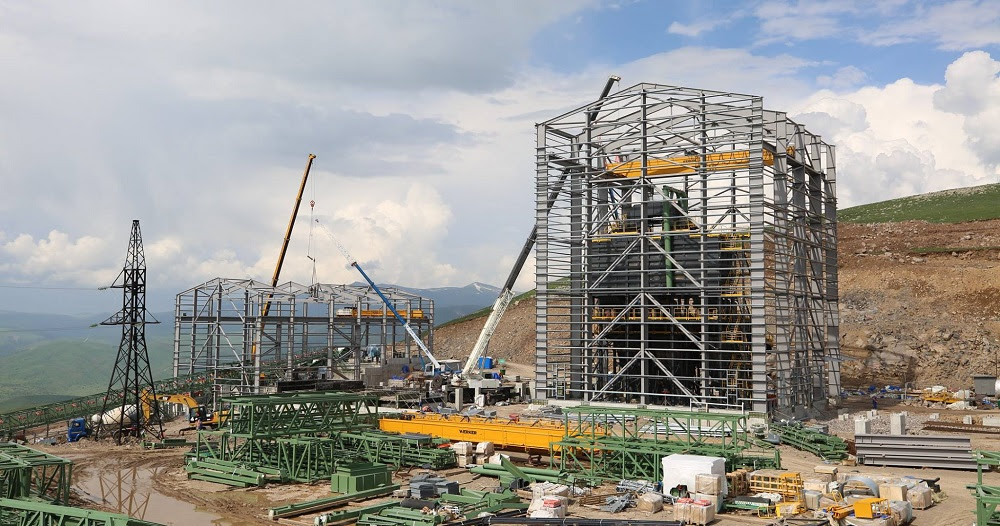

Furthermore, the Company has invested significant funds and 5 years of work to identify the environmental risks not only of the pad, but also all the infrastructre of the Amulsar mine, and to design the mechanisms of their management, involving about 50 international and national specialists and organizations, which is unprecedented for Armenia and also exemplary in complying with international standards.

2. “Which international standards envisage building the cyanide pad 500m far from the community, within the newly planted orchards of Gndevaz, if it is internationally accepted that such facilities should be 30 km far from the settlements?”:

We would be happy to familiarize ourselves with any regulatory document, according to which “it is internationally accepted that such facilities should be 30 km far from the settlements”.

We and numerous international experts who have worked on the Project are not familiar with any international standard which sets such a limited zone around the heap leach pad. As we have already mentioned, as long as the pad is properly managed and complies with technical requirements, it can operate safely in the neighbourhood of settlements.

In 2013 we visited the USA with the mayors of Gndevaz, Gorayk and Saravan and visited the Cripple Creek and Victor mines, where various infrastructure, including the heap leach facility, are 500m from the town of Victor and 900m from Cripple Creek. There are many other such examples.

The Amulsar pad will be 1 km away from the nearest community, Gndevaz, and at a considerably lower elevation.

Finally, Geoteam employees have been working closely with the inhabitants of the adjacent communities for 8 years, having established warm and friendly relationships with them. Most of our employees – engineers, geologists, social and environmental specialists – spend a considerable part of their working time at the communities and Amulsar. The safety of the communities and our staff is top priority for us, and we are working to assure this in the Project.

3. “You plan to use 2,000 tons of sodium cyanide per year. 4 million tons of solution will be obtained for preparing a solution with 500 mg/l concentration. You will pour out this 4 million tons in a year on the heap leach pad with an area of 134 ha and you plan to develop 2 ponds: collection ponds (with 200,000 m3 capacity) and HLF storm event ponds (with 170,000 m3 capacity). We would like you to explain what ecological calamity may be caused to Vayots Dzor by the 3.63 Mt cyanide solution and waters in 134 ha HLF area polluted by million tons of heavy metals, cyanide, hydrochloric acid from rainfalls and snowmelt, flowing into the Arpa River, as a matter of fact, all the villages irrigate the fields by the waters of Arpa”.

The heap leach is a closed cycle facility and there will be no industrial discharge to the Arpa River or any other environmental receptor.

Cyanide is used to extract gold from the ore stacked on the heap leach pad, which is designed to ensure there are no releases, thus preventing the possibility of both environmental and economic lossess.

The calculations of the author of the letter regarding the 3.63 Mt of cyanide solution is likely a result of misunderstanding. As mentioned in many sections of the EIA report, the cyanide solution will be supplied by a closed circulation system. This means that at a given period there will be 415-470 m3 circulating diluted cyanide solution in the pad, with about 230kg cyanide dissolved in approximately 460t water, which will be pumped back to the process without any emission. The cyanide and water content will be refreshed periodically, as the cyanide decays during the production process.

Now as for “million tons” of heavy metals: the metals to be extracted from the ore are the gold and silver, and the overall content does not exceed 350 tons of metal over the life of the mine. As for other metals, the ore naturally contains only trace concentrations. The concentration of the traces of metals in the ore in heap leach will not be more than it was in the rock naturally. Once again, the heap leaching is a closed circuit and neither the gold or silver nor the trace amounts of other metals will discharge into the environment. After the mine closure the heap leach will be rinsed for 12 months, cleaned from cyanide, drained down, covered with clay and topsoiled.

As for the snowmelt and rainfalls, again there will be zero discharge of process waters into the Rivers Arpa and Vorotan or other natural environment. The Surface Water Management Plan is summarized in Section 5.2.5 of the EIA and Appendix 16. The third pond out of those mentioned will be empty and will have 170 000m3 capacity. It is designed to collect storm event waters. All surface waters related to the production process will be collected by the drainage system and pumped back to the production process, as it is done in hundreds of modern mines in the world. Additional drainage will be built underneath the pad to collect snowmelt waters.

4. “Acquiring the lands for the heap leach facility and other infrastructures you will destroy the orchards and fields there. You are requested to make clear is it possible to use or sell to you as food the crops from the orchards and gardens several dozen meters far from that area.”

The majority of the orchards in Gndevaz are outside the land areas to be acquired by the Company. The areas to be acquired for locating the infrastructure will be demarcated and separated from the community lands. As already mentioned, the heap leach facility does not have process discharge and the materials used in the pad will not have any contact with the community lands.

However, despite all the safety measures in the design, it is natural that some of the inhabitants may have concerns about the potential impact on the orchards. Taking into consideration the potential of such concerns, the Company has undertaken an additional commitment to carry out monitoring of the produce from adjacent orchards, and to inform all stakeholders of the results.

The studies predict there will be no damage to the orchards adjacent to the HLF. Nevertheless, if it turns out that there has been any impact, inlcuding economic loss due to the activities of the Company, then the Company will be committed to compensate these losses.

Locally produced food will be an important source of supplies for the mine.

5. “You state that in the heap leach pad the pH of sodium cyanide should be 11 and more in order to change the acid to base, and there will be no hydrogen cyanide emission, a small quantity of which is killing. You are requested to explain how are you going to fulfill it in 134 ha area with 4 Mt solution under -30 to +300C temperature, in rain/snow, or what equipment will be installed on 134 ha area that 600 kg will be emitted when 20 tons of cyanide vapours pass through that device and 300 kg from 10t of hydrochloric acid. In case of fulfilling all this, whether the 4 Mt alkaline solution and 600 kg cyanadie, 300 kg hydrochlorid acid are not hazardous for the local residents and the ecology of the area.

To wrap-up the discussion of cyanide and to dispel the doubts on the “million tons” used in Amulsar, we’d like to say that IN TOTAL only 1.1 million tons of sodium cyanide annually is produced all over the world, with only 6% of this used in the mining industry worldwide. The remaining 94% is used in production of metallic (galvanical) materials, chemical fertilizers used in agriculture, paints, plastic, pharmaceutics, cosmetics and other production.

There is cyanide in nature as well. For example, the kernel of one bitter almond may contain 6.2 mg cyanic acid.

The kernels of apricot, apple, peach and more than 1,000 species of plants contain cyanide (according to the website of the International Cyanide Management Code).

As already mentioned, there will not be “million tons” of solution. The very dilute solution (500 mg cyanide in a liter of water, which is 0.05% cyanide) is circulating; there will be about 460t of solution in circulation at any given time. The statement on the hydrogen cyanide emissions is also a result of misunderstanding. The heap leach will not be generating any emissions of hydrogen cyanide. There is a small risk of hydrogen cyanide emission during the preparation of the reagents, which takes place in an enclosed facility within the process plant. As mentioned in Section 5.1 of the EIA, any possible emissions would be collected by the ultimate air ventilation system, and filtered in scrubbers. The circulating system in the scrubbers is formed by a diluted solution of sodium hydroxide, which absorbs vapours of cyanic acid and hydrochloric acid and neutralizes them. The effectiveness of the scrubbers is 97%.

Of course, as in the case of other chemical materials used in various industrial sectors, special safety measures are required for using the cyanide.

The Company has committed to obtaining, transportation, storage and use of cyanide in compliance with the requirements of the International Cyanide Management Code.

In accordance with the above Code and the Company’s preliminary Cyanide Management Plan, the staff working with cyanide in future will receive rigorous training to ensure safe storage and use of cyanide.

As for the pH, the internationally accepted way to ensure high pH is to add lime to keep the pH at level of 10.5 and to prevent generation of the hydrogen cyanide (gas).

As a further precaution, hydrogen cyanide gas detectors will be located at the cyanide mixing tanks and within the surrounding areas to identify even small amounts of emissions.

We have grouped the below-mentioned questions as the presented statements are not always followed by a relevant question.

The letter states the fact that the samples analysed by Geoteam contain other metals, besides gold and silver.

“(bismuth, cadmium, cobalt, chromium, copper, ferrum, gallium, molybdenum, nickel, lead, antimony, scandium, titanium, uranium, strontium, vanadium, zinc and wolfram) and toxic elements (arsenic, beryllium, thallium, selenium, mercury and cadmium), all of which are very toxic for human organisms”.

It is worth reminding that the mining operations at Amulsar have not been launched yet and current activities will neither increase nor decrease the metals concentrations in ore or soil within the project area.

Our studies show that the ore, water and soil within the surrounding area contain certain metals. In the analysed soil samples from the project area, concentrations of arsenic, lead, cobalt, copper, nickel and antimony are regularly found to be higher than Armenia’s Maximum Allowable Concentrations. It indicates that the concentrations of these metals are “naturally” elevated in the area, as a result of the characteristics of the underlying geological strata from which the soils are derived.

In addition, the sampling of waters has revealed elevated concentrations of the above-mentioned metals in the Vorotan, Arpa and Darb rivers. The springs and tributaries within the area also exhibit low pH, that is they tend to be acidic. Groundwater originating from beneath Amulsar is often similarly elevated in lead, nickel, copper and iron. Again, these “naturally” elevated metal concentrations reflect the underlying lithology. The concentrations of the metals are not expected to increase due to the mining.

“In the open pit area of 113.9 ha annually 12088.2 tons of explosives will be used: each well will be charged with 239.6 kg of explosives, 50452 explosions will be carried out, dust emission accounts for 761.56 tons per year and dust will be spread in distance of 100-1000m, noise level will be almost inaudible in adjacent communities. If the person, who made these calculations, had been to Amulsar, winds would have blown him off for 100 meters… Emissions in case of mine development will be as follows. Inorganic dust – 1185.8 t/y, Nitrogen dioxide – 1365.86 t/y, Carbon monoxide – 1107,75 t/y, Hydrocarbons – 222.4 t/y, Hard particles – 113.92 t/y, Sulfur dioxide – 106.35 t/y. We would like you to clarify the ecological impact in the area and Vorotan-Arpa Tunnel.”

The calculations have been made by international and local specialists who have been visiting Amulsar and making wind measurements, during different seasons, within 6 consecutive years and comparing them with Armenian Hydrometeorological Service data. A dust settlement model has been developed as part of the environmental studies. According to this model, the dust generated by blasting will mostly settle within a 100 meters’ radius and the small particles within a 1000 meters’ radius of the open pit. Gorayk, which is the closest community to the open pit, is located at a distance of 4 km.

Amulsar is not the most challenging deposit in terms of climate. There are a lot of other projects in the world that are being operated in much more challenging climatic conditions, including those located in close vicinity of cities. For example, the Swedish Kiruna deposit that is just adjacent to the city.

The modern blasting methods make it possible to significantly reduce emissions.

The composition of the dust was estimated from chemical analysis of more than 20,000 samples of ore rock and more than 50,000 samples of barren rock, and modelling was then undertaken to estimate the resulting concentrations of the elements in the soil (due to dust settlement) at the end of mine operations.

The element concentrations were then compared with both ecological and human health screening criteria and were concluded not to present a risk to either cattle grazing on the soils or to humans drinking milk or eating beef from the cattle.

With respect to the impact of blasting on the Vorotan-Arpa tunnel, a preliminary assessment has indicated that there is no risk. The tunnel is 3 km horizontally and 1km vertically removed from the open pits where blasting will take place, and is in a different geological environment.

“Barren Rock Storage Facility is located in the area of 140 ha in a distance of 5 km from the open pit and 7 km from Kechout reservoir, which is located in the drainage basin of Kechout and Spandaryan reservoirs. Annually around 46.7 million tons of ore and 10 million tons ore will be transported here, which will be crushed with three crushers located in a distance of 4.5 km, and then transported via four overland conveyors, on a 1200mm wide belt, for 7.2 km up to track stucking spot adding thousands tons of sodium hydroxide. Afterwards 3 trucks of BelAz–7513 make will transport them to the heap leach facility located in a distance of 1 km. If we spread the crushed ore in the area of 134 ha, we will get a layer of 8 meters high…”

To clarify, barren rock is not crushed; it is taken directly from the open pit to the Barren Rock Storage Facility. It is the ore that is crushed. The conveyor will be covered to minimize the dust emission. Lime will be added to the ore before placement on HLF to neutralize the acidity.

“….where you mention that dust emission of one ton of ore will make up only 1.5 grams after passing the filters of three crushers, a technology any pharmaceutical plant will be jealous of.”

The mentioned figures are a reality for many modern mining operations. And this is how it is done: the primary crusher building, secondary/tertiary crusher building, and screening building are all enclosed structures, and each building will be fitted with a separate dust collection system. Dust hoods will be placed over the conveyor transfer points and crusher feed points within the crushing and screening buildings. Thus, emissions will be very low.

Finally, about the economic benefits, Jermuk, inconsistence of the future mining and agriculture, as well as the developments, following the mine-closure in 13 years.

Briefly, on figures. The Project is the largest private investment project in Armenia at the moment. According to preliminary estimates, the Project will contribute an estimated USD 488 million to the budget of the RA during its operational life, in the form of taxes and royalties. Another USD 156 million will be paid as taxes due to operation of other associated small and medium business entities. The wage fund will make an estimated USD 230 million. The annual average effect on the overall GDP of Armenia is calculated to make some USD 120 million. This is a good opportunity for an economic effect, which is obvious even for a non-economist. It will create many investment opportunities for community development, agriculture, tourism and other sectors both in Jermuk and surrounding communities. The efficiency of the funds application, the strategic investments and the management will depend on the joint efforts to be taken by all the parties, namely the communities, State authorities, civil society and, to a certain extent, the company. On the effective management of the investments within the 13 years will depend the economic sustainability.

As to the compatibility of agriculture and mining, this will be possible if correct management is provided. There are many examples of countries that have both large agriculture and mining sectors – the US, Australia, Brazil, Canada, Argentina and Spain among them.

The Amulsar mine closure process is planned to meet all the international standards. It is worth mentioning that around USD 10 million is stipulated for the mine closure, including environmental, social and land and water management plans.

And lastly, we would like to remind that all the above-mentioned figures, percents and industrial processes descriptions represent a well-tested and widely used technology.

The lack of trust in mining is easy to understand and the concerns and anxiety are fully legitimate and appropriate considering the previous experience of Armenia.

However, there are hundreds of operating mines in the world now and many are modern and well-managed operations. The mining sector, just like the other industries, has reported a fast technological growth over the last decades. Some of the deposits in developed and developing countries apply the above-mentioned practices and environmentally sound management and provide economic benefits for the country.

We believe that it will be possible to achieve the same in Armenia as well. However, we understand the concerns and are ready to continue the dialogue and arrange meetings with international experts as requested by the authors of the letter.

Geoteam