Introduction

Lydian has published a revised NI 43-101 technical report (Lydian International, 2019; “Technical Report”) for the Amulsar Project in Armenia. The Canadian National Instrument (NI) 43-101 Standards of disclosure for mineral projects is a set of rules and guidelines for reporting and displaying information related to mineral properties owned by, or explored by, companies listed on stock exchanges in Canada. The focus of the NI 43-101 is disclosure with professional accountability, and the core principles rest on the Qualified Person, using standards and best practices, and producing a Technical Report (TMX and Ontario Stock Exchange, 2018). A Qualified Person must meet certain ethical, education, and experience requirements.

The revised Technical Report claims higher reserves based on a re-evaluation of existing information with no additional drilling. It is unclear if the projected environmental effects are based on a similar re-evaluation or simply reflect past reporting.

An “advanced property” is required to discuss environmental studies, permitting, and social or community impact in its Technical Report because water, tailings, and waste are critical areas of project risk (TMX and Ontario Stock Exchange, 2018, p. 107, 113). The disclosure essentials for advanced projects also stress the importance of obtaining and maintaining the “social license” to operate. The environmental risks of the Amulsar Project and the lack of a social license are seriously underrepresented in the Lydian (2019) Technical Report. I present information on these two topics in the memorandum, with a focus on environmental risks.

Read also

Environmental Risks

The Qualified Person for the NI 43-101 report is responsible for communicating the project risks and clearly report on the material risks in a manner understandable to investors (TMX and Ontario Stock Exchange, 2018, p. 19). The NI 43-101 further requires that public reporting of technical information is clear, transparent, balanced, not misleading, and based on reasonable, clearly explained assumptions. Public reporting must also be unbiased and identify the potential risks and uncertainties (TMX and Ontario Stock Exchange, 2018, p. 22).

Risks Related to Acid Rock Drainage are Misleading and Not Based on Clearly Explained Assumptions

Acid mine or acid rock drainage is widely acknowledged as the most important and serious environmental and water quality risk associated with hardrock mining operations such as the Amulsar Project (see, e.g., U.S. Department of Agriculture, 1993). Lydian has acknowledged that acid rock drainage (ARD) at the Amulsar Project is a risk for the waste rock (barren rock storage facility, or BRSF), the pit wall rock, and the pit backfill (Lydian, 2019, p. 1-16). The extent of the risk, however, is downplayed in Lydian’s Technical Report:

“Using industry-practice mitigation measures, the ARD has been shown to have no significant local or regional water quality impact (Wardell Armstrong, 2016).” (Lydian, 2019, p. 1-16)

While methods to minimize ARD generation are described in Lydian’s report (see, e.g., for the BRSF on p. 18-8 land 18-9), Lydian does not describe how these methods will result in “no significant…impact” of ARD or whether or not the methods are industry best practice, as required by NI 43-101 (throughout TMX and Ontario Securities Commission, 2018).

Encapsulation is Lydian’s primary method proposed to “prevent the generation of ARD” from the BRSF (Lydian, 2019, p. 18-9). The GARD Guide, a compilation of industry best practice for ARD management, discusses the use of acid-consuming materials in encapsulation.1 However, Lydian is not proposing to add acid-consuming (i.e. neutralizing) material to the BRSF for encapsulation. Instead, Lydian is assuming that compaction from truck traffic and the presence of argillic clay minerals will seal off the acid-generating waste rock from contact with infiltrating water or melting snow (Lydian, 2019, p. 18-9). The waste rock in the BRSF and the pits will likely be the largest source of ARD from the Amulsar Project, and the Technical Report presents a plan for increased reserves, which will result in the production of more waste rock (p. 1-1).

According to Lydian (2019, p. 25-32), Golder produced a seepage model “showing the encapsulation to be an effective ARD mitigation measure” that would reduce seepage to 2 L/s during spring runoff at the 50% base-case condition. This mid-range calculation does not represent potential high-flow conditions under which the seepage rate would be higher than 2 L/s. The 2019 Golder report is not available on either the Lydian International or Lydian Armenia websites, and from the title it does not appear to be related to ARD mitigation. Lydian also uses the Technical Report to summarize new information on ARD geochemical characterization that is not available on their websites (GRE, 2019, discussed below). Therefore, the NI 43-101 requirement for transparency and clearly explaining the material risks and associated uncertainties is not met for this important claim about preventing or minimizing one of the largest risks associated with the Amulsar Project.

An independent third-party review of Lydian’s most recent Environmental and Social Impact Assessment (ESIA; Wardell Armstrong, 2016) was conducted by ELARD and TRC (2019). An assessment of Amulsar’s ARD potential was conducted by GRE in 2017 (GRE, 2017). The ELARD and TRC (2019) review calls the GRE assessment “misleading,” because, among other reasons, it “underestimates the potential for ARD generation and the associated water quality, environmental impacts, and water treatment requirements” (ELARD and TRC, p. 27). A more recent ARD assessment by GRE (2019) is cited in Lydian (2019), but this document is not available on Lydian’s website. Because the report is not publicly available, it is unclear if it addresses the increased planned production and generation of acid-generating material. However, the geochemical testing result figures in the 2019 Technical Report are identical to those in the 2016 ARD Management Plan submitted with the 2016 ESIA. Therefore, it must be assumed that no new geochemical testing has been conducted on the additional waste rock produced from mining the additional reserves. Underestimating acid generation and contaminant leaching potential will underestimate the severity and extent of environmental impacts and result in proposing inadequate mitigation measures, including water treatment approaches (Prabhakar-Fox and Lottermoser, 2015). Because once ARD forms it can continue for centuries, such underestimates can have potentially long-term consequences and can notably affect the economics of Lydian’s operation.

The ELARD and TRC (2019) review is mentioned in Lydian’s Technical Report (see, e.g., p. 4-13). Parts of the ELARD and TRC (2019) review are on Lydian Armenia’s website (only as a “rough translation”), with responses from Lydian, the expert group (ELARD), and the RA Investigative Body.5 However, the full review by ELARD/TRC is not on their website, nor is the list of TRC’s recommended mitigation measures (TRC, 2019), most of which Lydian agreed to. These omissions are an example of low transparency by Lydian, and the reports should be included in a corrected NI 43-101 report. The list of recommended mitigation measures is on the RA Investigative Committee website, as is the ELARD/TRC review. These important documents should also be put on Lydian’s website to meet the transparency requirements of NI 43-101.

In the response document3 the conclusion by the Republic of Armenia Investigating Body rests on the following statement “…if Lydian planned mitigation and closure measures and the above supplemental and contingent mitigation measures are adequately and verifiably planned, modeled, designed, implemented, operated, monitored, and maintained during the operation and post closure phases, the environmental risks to nearby water resources (groundwater, and major rivers and springs) should be manageable.” This refers to the “about 16 mitigation measures recommended by ELARD/TRC.” In other words, the Armenian government is stating that they will have more confidence in the environmental behavior of the Amulsar Project if these mitigation measures are implemented and maintained. However, Lydian does not mention the mitigation measures in their Technical Report and has not accounted for the increased costs of implementing the recommended mitigation measures. This omission from Lydian’s NI 43-101 is serious and should be corrected in a revised NI 43-101 that transparently states what the mitigation measures are and how much it would cost to adequately and verifiably plan, model, design, implement, operate, monitor, and maintain them during operation and through to post-closure.

Risks and Costs Related to Mine Water Treatment are Underestimated

As noted, the ELARD and TRC (2019, p. 27) review states that the ARD assessment for Amulsar underestimates the potential for water treatment requirements. Lydian has contradictory statements in its Technical Report and other documents about the need and costs for mine water treatment during operations and closure. These assumptions and omissions and the lack of specificity translate to a lack of transparency and increased risk for investors.

Lydian believes mine water treatment will be needed for the BRSF in Year 4, which is during operations, and for the heap leach facility (HLF) in Year 15, which is during closure (Technical Report, p. 21-10). However, no costs are included for water treatment during operations, with the exception of a single line item for workers’ potable water (p. 21-6). The Technical Report mentions capital and operating costs for passive mine water treatment in the closure section (p. 21-10) and says treatment costs are included in closure costs (Table 21-10), but the values are only presented on an annual basis with no specificity about what is included or excluded.

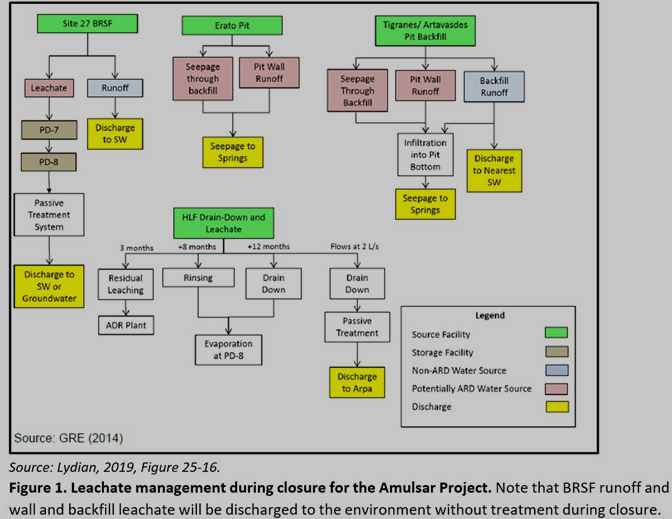

Lydian states in its response letter to the government of Armenia (Lydian Armenia, 2019) that leachate from the BRSF will not need treatment during closure because the cap system will “prevent any rainfall” from contacting waste rock – thus reclassifying BRSF runoff as non-contact water during closure. It is highly unlikely that the cap and evapotranspiration layer mentioned will be 100% effective, yet this is Lydian’s assumption. Figure 26-16 in the Technical Report (reproduced as Figure 1 below) shows passive treatment of BRSF and HLF leachate during closure but no capture or treatment of runoff from these facilities. The figure also shows that leachate from Erato and Tigranes/ Artavasdes pit backfill and walls will not be treated during closure. Lydian assumes that the backfill will be 100% non-acid-generating (“NAG”; Lydian Armenia, 2019) and will not leach metals or other mine contaminants to the environment in concentrations that could create water quality risks. This assumption contradicts waste rock leach test results, is overly optimistic, and is not accounted for in contingency measures or costs.

Lydian issued a response letter to the ELARD and TRC (2019) review (Lydian Armenia, 2019). The letter states “…the Company commits not to discharge any untreated contact water from the site to the environment” (emphasis added). Lydian’s definition of contact water is too limited. The Technical Report divides water at the mine into three categories: contact, impacted, and non-contact, with “impacted” water including runoff from haul roads, crushing, the conveyor, non-acid generating waste rock, and topsoil stockpiles. Runoff that contacts ore (from the crusher and conveyor) and waste rock is considered contact water and is normally sent to the contact water pond for monitoring and treatment. Lydian declares, without requiring monitoring, that “impacted” water will be lumped with non-contact water because “…this water is assumed to not require additional treatment prior to release to the environment.” (Lydian, 2019, p. 18-13). By creating a term and a non-standard definition, Lydian is again underestimating risks and costs for mine water treatment that will be needed at Amulsar.

Further, Lydian contradicts itself later in the Technical Report by saying that all water coming into contact with waste rock, pit walls, or spent ore is considered contact water and will require treatment (p. 25-28):

“Furthermore, the water quality from all barren rock and from the spent heap leach material is not expected to meet regulatory discharge standards without treatment and management. As a result, all water coming into contact with barren rock, pit walls, or spent HLF material is considered contact water and must be managed accordingly”

The inconsistencies in the Technical Report are an indication that Lydian has not carefully evaluated the characterization of mined materials and is at best confused about the types of mine water that will be generated and the extent and type of treatment that will be required.

Lydian assumes for purposes of water treatment, that the Upper Volcanics (UV) material will not generate acid (Technical Report, p. 25-16). According to Table 25-12 in the Technical Report, most waste rock in the BRSF will be from “NAG” UV and colluvium material, and the backfill will be an even split of UV/colluvium and Lower Volcanics (LV) material. An inadequate number of longer term (kinetic) tests were run on UV waste rock. The three UV kinetic tests shown in Figure 25-8 demonstrate that two tests were prematurely stopped, and the one that continued beyond 20 weeks did produce acidic leachate with a pH below 6 (cutoff for acidic leaching according to the industry-sponsored GARD Guide). The Technical Report also describes three categories of LV waste rock: strongly, mildly, and non- acid generating (p. 25-26 – 25-27). However, the pH values produced for all categories are acidic, with the “NAG” category producing “pH with a leachate of ~4.8.” More testing is needed, but the limited results suggest that “NAG” waste rock, which will be placed in the BRSF and as backfill in the pits, will generate acid. As noted, contact water runoff and leachate from pit walls and backfill will be discharged to the environment without treatment.

Regardless of whether acid is produced, waste rock can release metals and other mine contaminants. The short-term leach test results showed that waste rock leached concentrations of barium, copper, iron, manganese, nickel, and sulfate that approached or exceeded regulatory discharge standards (Technical Report, p. 25-21). The limited static and kinetic testing results strongly imply that, especially with longer leach times, waste rock leachate will require collection and treatment well into closure. Lydian assumes only limited treatment of BRSF drain down water will be needed during closure and post-closure.

Lydian commits “…to apply active treatment if its passive treatment system fails to ensure the necessary result” (Lydian Armenia, 2019). In the letter, Lydian mentions using lime dosing of contact water prior to passive treatment as an “active” treatment approach, if needed, yet this approach is not mentioned in the Technical Report, which post-dates the letter. In a broader sense, Lydian does not include contingency costs for active treatment, which will be substantially more expensive than passive treatment, in the Technical Report.

Costs for mine water treatment need to be more clearly described in a revised Technical Report, and assumptions about the need for treatment need to be better supported. Including realistic costs for treatment of all contact water during operation, closure, and post-closure will increase costs and could change Amulsar from the “low cost” operation touted by Lydian to a higher cost mine with higher environmental risks.

Social License to Operate

Obtaining and maintaining a social license to operate is a critical element for mines (TMX and Ontario Securities Commission, 2018, p. 114). The license to operate in this context must be granted by the communities and has been ranked as the number one business risk for the mining sector in 2019/2020 (Mitchell, 2018).

Lydian states in its Technical Report that “… local people are generally supportive of the project.” (p. 1-16). At the same time, as they note, “A continuous illegal blockade at Amulsar has been in place since 22 June 2018, causing construction activities to be suspended since this date. Access has generally been limited to activities related to contractor demobilization and winterization.” (p. 1-17).

Communities are often split about mining due to concerns about the environment and their traditional, pre-mine livelihoods versus new, potentially higher paying jobs. Regardless of the local consensus on the project, Lydian stated in June 2019 that it has lost more than $60 million since the protests began (in one year; Bacchi, 2019).

Ongoing protests would continue to risk the financial success of the project, and lack of financial success threatens environmental compliance, especially for a company like Lydian that has no prior experience in the sector. A failure in environmental compliance that risks the health or safety of communities or the environment will likely restart the protests. Lydian is proposing a Community Support Recovery Plan, and costs have been included in its G&A costs in their Technical Report (p. 20-32). But the plan and the proposed audits will not necessarily stop the blockades. The impact of future protests and blockades has not been factored into Lydian’s financial disclosure. As noted in its Table 26-1 Project Risks, Lydian acknowledges that the ongoing problem with its social license to operate would only move from Critical to High with the implementation of the Community Support Recovery Plan. Given the failure of Lydian and the government to stop the ongoing protests, it seems their prediction may be overestimated, and the risks would be Critical for the foreseeable future.

Summary

Lydian’s 2019 NI 43-101 Technical Report underestimates risks, costs, and associated uncertainties for its Amulsar Project and in so doing fails to adequately meet the disclosure, professional accountability, and transparency requirements of NI 43-101. The information in the Technical Report contradicts the statement of no identified risks (except ability to secure permits) on p. 1-10 and strongly suggests that development of the project will be affected by known (based on limited waste characterization results) and unknown (because of a lack of adequate waste characterization) environmental and social risks. The risks will result in higher operational and closure costs than estimated by Lydian. Importantly, all waste rock produced at the site will generate acid, according to Lydian’s limited geochemical testing results. A revised NI 43-101 Technical Report should be completed that addresses these inadequacies and includes appropriate costs.

References Cited

Bacchi U. 2019. “Gold of contention: Armenia land dispute in spotlight as government steps in.” Reuters. June 5. https://www.reuters.com/article/us-armenia-mine-protests/gold-of- contention-armenia-land-dispute-in-spotlight-as-government-steps-in-idUSKCN1T701D

ELARD and TRC. 2019. ESIA Review. Independent 3rd Party Assessment of the Impacts on Water Resources and Geology, Biodiversity and Air Quality. Prepared for: Investigative Committee of the Republic of Armenia. July 22. http://investigative.am/images/2019/lidian/porcaqnnutyun/amulsar11.pdf

Lydian International. 2019. Feasibility Study Technical Report, Amulsar Project, Armenia. Report data: October 15. 417pp. https://www.lydianinternational.co.uk/images/TechnicalReports-pdfs/NI- 43-101-Amulsar-Technical-Report-2019-10-15-final.pdf

Lydian Armenia. 2019. Letter to Mr. Yu. Ivanyan, Head of Department for Investigation of Corruption- related Property Crimes and Cybercrimes, RA Investigative Committee. From Hayk Aloyan, Managing Director of Lydian Armenia CFSC. 15 August. 9pp. (response to ELARD and TRC, 2019, report). https://www.lydianarmenia.am/Lydians_position_ENG.pdf

Mitchell P. 2019. “The top risks facing mining and metals in 2019-2020 reflect a new era of disruption from both within and outside of the sector.” EY Global Mining & Metals Leader. December 4. https://www.ey.com/en_gl/mining-metals/10-business-risks-facing-mining-and-metals

Parbhakar-Fox, A. and Lottermoser, B.G. 2015. A critical review of acid rock drainage prediction methods and practices. Minerals Engineering 82, 107-124. http://www.sciencedirect.com/science/article/pii/S0892687515001053

TMX and Ontario Securities Commission. 2018. Mining Disclosure Essentials: NI 43-101 reporting fundamentals, industry best practices, and useful guidance for TSX and TSXV issuers. Presentation, 126pp. https://www.osc.gov.on.ca/documents/en/Securities- Category4/ni_20180307_43-101_mineral-disclosure.pdf

TRC. 2019. Supplemental Mitigation and Contingency Measures Considerations. Memorandum to: Yura Ivanyan – Investigative Committee of the Republic of Armenia (ICRA), From: Nidal Rabah, David Hay, and Robert Stanforth, TRC. July 22. http://investigative.am/images/2019/lidian/porcaqnnutyun/amulsar.pdf

U.S. Department of Agriculture, Forest Service. 1993. Acid Mine Drainage from Impact of Hardrock Mining on the National Forests: A Management Challenge. https://archive.org/details/CAT31108485

Wardell Armstrong LLP. 2016. Amulsar Gold Mine Project. Environmental and Social Impact Assessment (ESIA). June 2016. https://www.lydianarmenia.am/index.php?m=publications&lang=eng&p=99